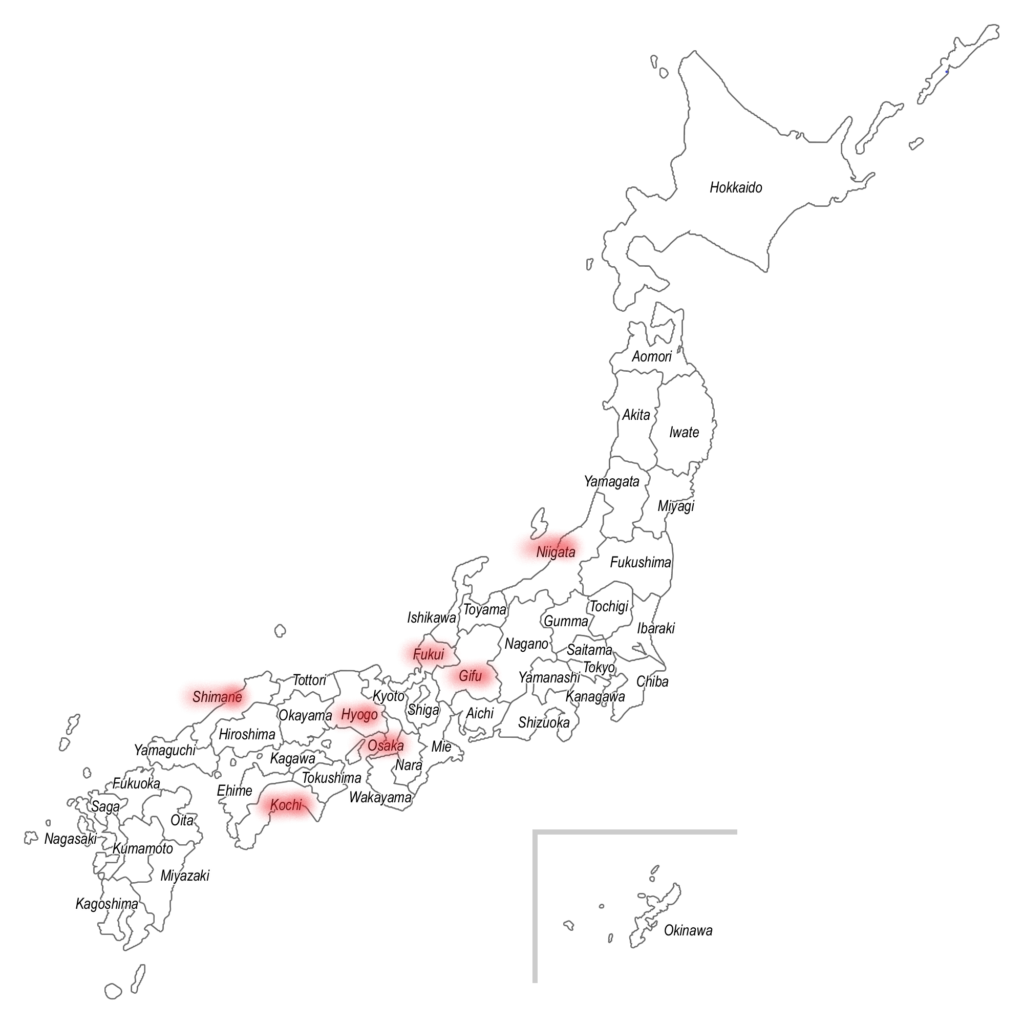

In Japan, kitchen knife makers who inherit the lineage of traditional technology, knife makers are concentrated in Tsubame Sanjo in Niigata Prefecture, Seki City in Gifu Prefecture, Sakai City in Osaka, Miki City in Hyogo Prefecture, Tosayamada in Kami City in Kochi Prefecture, etc.

These are also the famous producing areas of Japanese cutlery. High-quality kitchen knives are known to have a high reputation in the world, and each company develops a unique brand. Below is a list of kitchen maker manufacturers, steel materials used for kitchen knives, and selection methods.

Table of Contents

A famous production Area for Kitchen Knives in Japan

The table below summarizes the regions and brands that make domestic kitchen knives’ famous production areas and gems called masterpieces.

Even if you talk about “kitchen knives”, we are particular about Japanese products, manufacturers that balance affordability and quality, manufacturers that use improved steel with a long history unique to the region, innovative designs and future orientation. We have various directions such as manufacturers, brands handmade by craftsmen, manufacturers who are particular about professional specifications, etc.

Originally, the Japanese sword itself was backed by the technology of refining steel and the advanced technology of blacksmithing, and think it is well known that it has excellent performance compared to the blades of other countries. A famous production area for cutlery is also a region that has traditionally inherited the genealogy of these technologies and inherited the manufacturing and development of cutlery while incorporating modern technology. In that sense, kitchen knives can be said to be a product that makes you feel familiar with the high level of Japanese steel and blacksmithing technology.

A list of Japanese Knife Makers

Below, I will introduce kitchen knife makers and brands for each of the major production areas of cutlery. I have put in links of each company’s homepage.

Some company don’t have English options but you can still enjoy the differences of each companies.

A cooking and precision knife manufacturer located in Sanjo City, Niigata Prefecture. It has a history of being founded as a Sanjo knife blacksmith that has continued for more than 140 years. Soft and hard stainless steel was forged alternately using high-quality blade steel V-Kin No. 10 containing cobalt, a water-sharpened blade by a craftsman, an all-stainless Verdun, a square horse with a main-sharpened water-abrasive blade, and cobalt. There is a lineup of kitchen knives such as UN-RYU with a Damascus pattern.

Well known as GLOBAL knife.

Established in 1954, Yoshida Metal Industry (YOSHIKIN) were born as a manufacturer of western tableware, which is a main industry at the Tsubame – Sanjo region in Niigata Prefecture.

In 1960, the stainless steel “Civilization Gincho(文明銀丁)” was launched, and the GLOBAL series has been released worldwide since then. Stainless steel containing molybdenum and vanadium is used for the blade. A kitchen knife with a streamlined shape that is all stainless steel from the blade to the handle, is resistant to rust, and is beautiful and easy to grip.

I love this knife. I am using GLOBAL santoku knife for myself too. It is very light, easy to grip and easy to sharp.

A kitchen knife maker in Tsubame City, Niigata Prefecture, featuring the technology of “cutting blades”. One of the few integrated kitchen knife manufacturers in Japan. The steel materials used are also abundant, and the lineup is diverse. There are many lineups that use cobalt alloy steel for the core material and a composite material that sandwiches the sides with stainless steel with excellent corrosion resistance.

A kitchenware manufacturer founded in 1967 with its headquarters in Sanjo City, Niigata Prefecture. It has a wide range of houseware in its lineup, but as kitchen knives, there are series such as Hikou, Hiken, Hikyo, Hiyu, and Hiarashi from Damascus style to all stainless steel.

Knives workshop Tadafusa is in Sanjo, Niigata prefecture. It is characterized by being thinly and delicately sharpened. Tough alloy steel such as blue steel (Aogami) and SLD steel (die steel) is used for the core material (mixed material), and composite materials that wrap both sides of the core with stainless steel are mainly used.

A comprehensive knife maker with roots in a knife maker founded in Seki City, Gifu Prefecture, which also handles kitchen utensils and confectionery supplies. Launched high-end line knives such as “Shun(旬)”, which sold more than 5 million knives worldwide, and “Seki Magoroku(関孫六)” by swordsmith Mr. Kaneko Magoroku.

Those knives (旬、関孫六)are very popular here in the UK. Many of my colleagues have one. I am sure it’s because you can find easily from Amazon and there are varieties.

A kitchen knife manufacturer in Seki City, Gifu Prefecture. Seki City is said to have more than 300 swordsmiths during the Muromachi period. Seki’s sword, which is said to “do not break, do not bend, and cut well,” has a history of 700 years. Under the 霞 KASUMI brand, we have developed the VG-10 PRO series, which uses 100% Damascus steel, titanium coating, and VG10 as solid wood for the blade. Innovative designs and shades of kitchen knives are also on the market.

Another popular Knife in the UK. I actually never tried this knife. Some of my colleagues have one, they tend to have mostly Santoku knife however I would love to try their Yanagiba(柳刃)like a picture below on the right. I’m sure it must be cool.

I was gonna introduce some knives from Amazon but everything is too expensive and doesn’t seem like cool. I will update some more useful info soon.

A specialized manufacturer of kitchen knives with its head office and factory in Seki City, Gifu Prefecture. There are UX10, 440, 440PH, molybdenum steel, EU carbon steel series, etc. bearing the name of the steel type used. The name of the steel material used is written on the blade.

I have one Molybdenum steel Salmon Sujihiki. it’s beautiful blade, easy to sharpen but keeps its sharpness long.

Specialized manufacturer of cooking knives that has been making cutlery in Sakai, Osaka for 120 years. Showroom is also available. It has a lineup that seeks to maintain sharpness as well as sharpness.

The website supports international shipping.

A kitchen knife manufacturer that manufactures Sakai cutlery. Sakai cutlery is a traditional cooking utensil of its 600 years history. There is a wide variety of kitchen knives, and there are many variations of steel materials. Highly trusted by professional cooks

Founded in 1926, a kitchen knife maker in Sakai, develops the Sakai Kikumori(堺菊守), Chouyou(重陽) series. The voice of a professional cook is reflected in every detail to pursue ease of use, and first-class craftsmen make every effort from fire making to sharpening.

A knife maker in Echizen City, Fukui Prefecture, known for Echizen Uchihamono. Echizen Uchihamono has a long history, as it is said to have taken root in 1337 (Nanbokucho period) when the swordsmith Chiyotsuru Kuniyasu of Kyoto sought a suitable place for sword production and moved to Fuchu (currently Echizen City).

A long-established knife maker in Miki City, Hyogo Prefecture, which has been in business for over 70 years. Miki City’s cutlery has also been designated as a traditional craft, also known as Banshu Miki Uchihamono. Around the end of the 16th century, it developed as a hardware town.

Since its founding in 1946, it has been manufacturing kitchen knives in Miki City, Hyogo Prefecture, which has both the highest level of sharpness and price that can be convinced by professionals. The origin of Banshu Miki Uchihamono is said to date back to the introduction of technology from Kudara(百濟)in the 5th century.

Tosa Uchihamono with a history of 400 years. Has a good reputation for Yanagi blade knives and Deba knives. Tosa cutlery must meet the conditions in the material and manufacturing method. The material is iron and carbon steel, and it is intended to be carried out by hammering and spreading. Quenching of sickles, kitchen knives, hatchets and patterned sickles is a traditional method of quenching by “mud coating”. Strain removal, blade attachment, sharpening, and finishing are done by hand. The handle is wooden.

A long-established knife maker that originated in Germany. A traditional brand dating back to 1731. Famous for the Zwilling brand known for the twin mark and the Henkels brand for the one-person mark.

Kitchenware series designed by famous industrial designer Sori Yanagi. A product planned and manufactured by Sato Shoji and jointly developed. Molybdenum and vanadium steel are the main kitchen knives.

Although it has a wide range of business areas, it originally possesses advanced fine ceramics technology and commercializes ceramic knives. Ceramics have a hardness that surpasses that of metals, but due to their toughness, care must be taken in terms of cracking and chipping.

Conclusion

There are so many varieties and options to buy even one knife. It might be confuse you, however getting to know how your knife made by or where your knife come from is very interesting and it gives you more knowledge when you actually use yours in the kitchen.

Hope this article helps you buying your beautiful knife.